Product Description

| (25℃)MOTOR PARAMETER | ||

|---|---|---|

| NominalPower | W | 2.0 |

| Rated Voltage | Volt | 12 |

| Resistance ±10% | Ohm | 10.00 |

| No-load Speed ±10% | rpm | 6500 |

| No-load Current ≤125% | mA | 15 |

| Speed Constant | rpmV | 542 |

| Torque Constant | mNm/A | 17.42 |

| Stall Current | mA | 1200 |

| Stall Torque | mNm | 20.90 |

| Max.Efficiency | % | 79 |

| Inductance | mH | 0.5 |

| Mechanical Time Constant | ms | 3.53 |

| Rotor Inertia | gcm² | 1.08 |

| At Max.Output | ||

| Current | mA | 200 |

| Torque | mNm | 3.48 |

| Speed | rmp | 5417 |

| Output | W | 2.0 |

| MOTOR CHARACTERISTIC | ||

| Ambient Temperature Range | -40~+80℃ | |

| Max.Permissible Winding Temperature | 155℃ | |

| Number Of Commutator Segments | 5 | |

| Weight | 32g | |

| Precious Metal Brush |

|

|

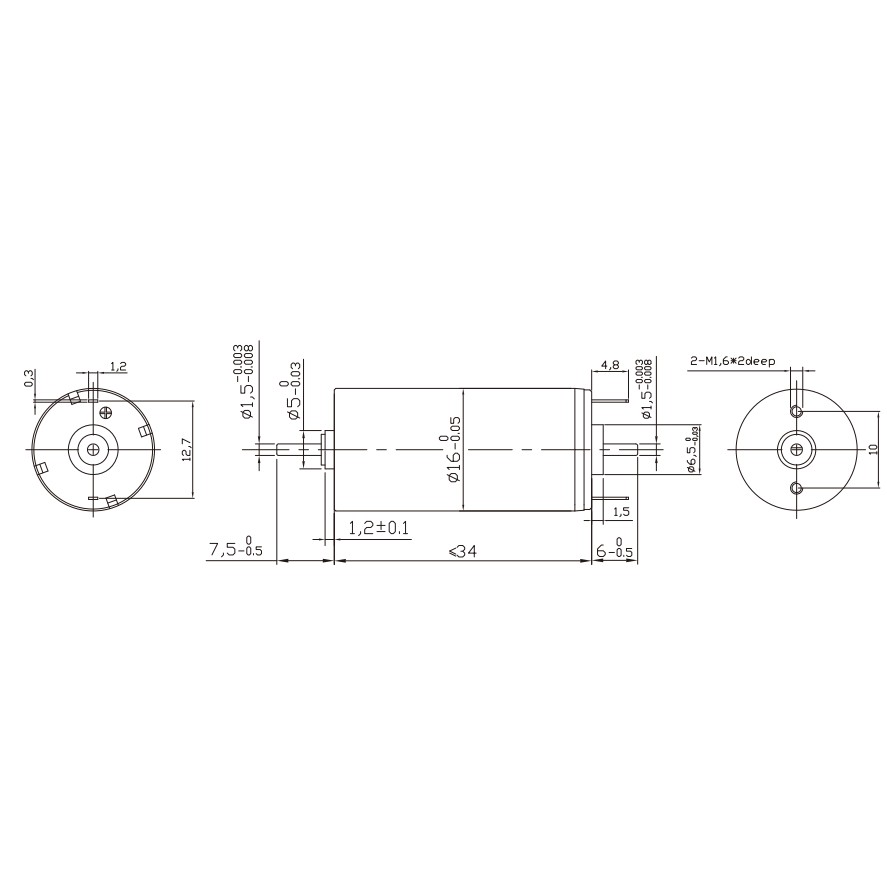

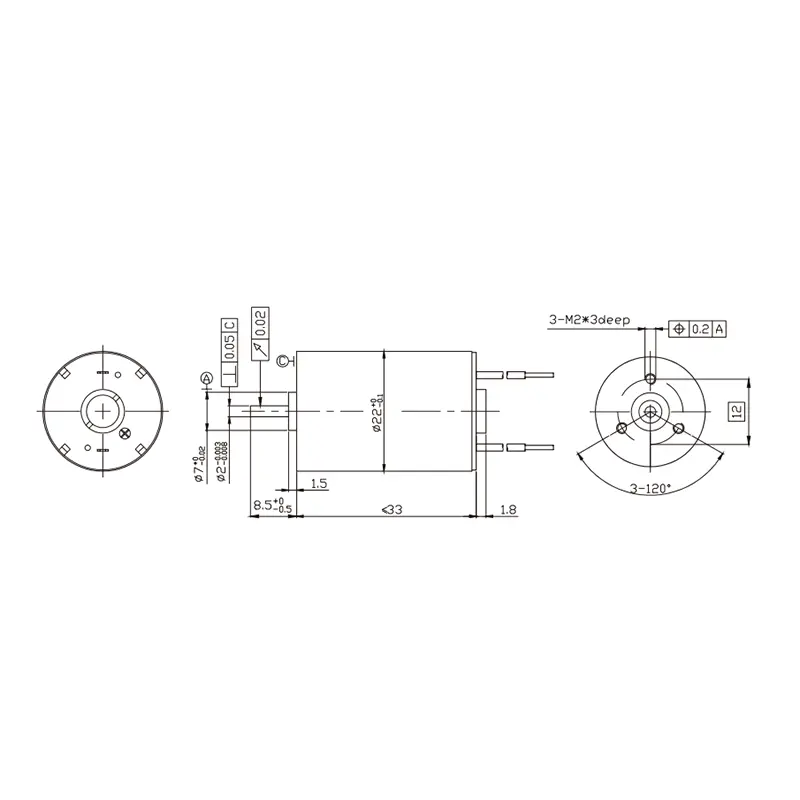

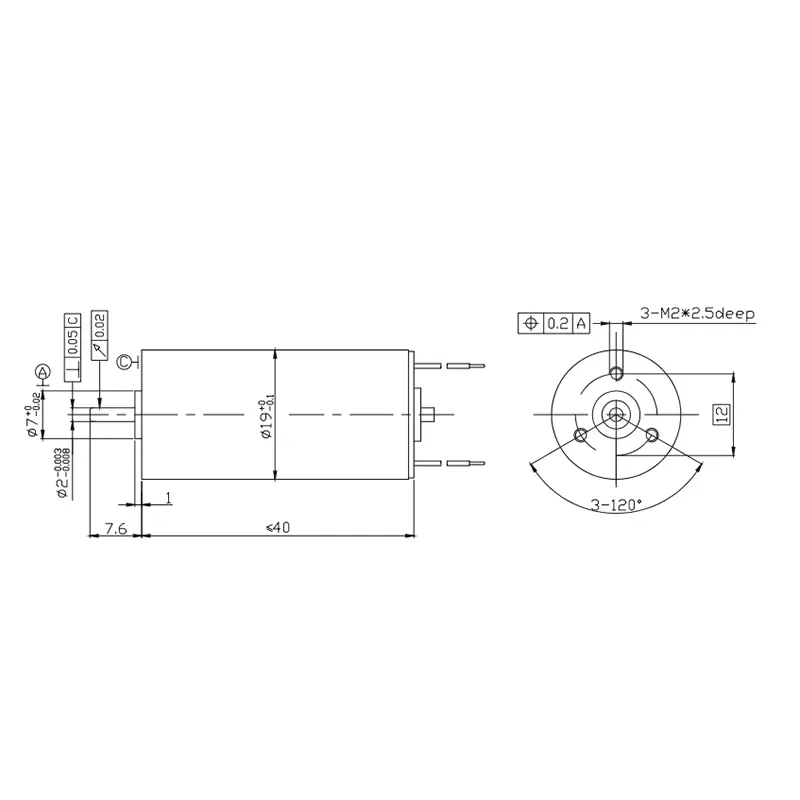

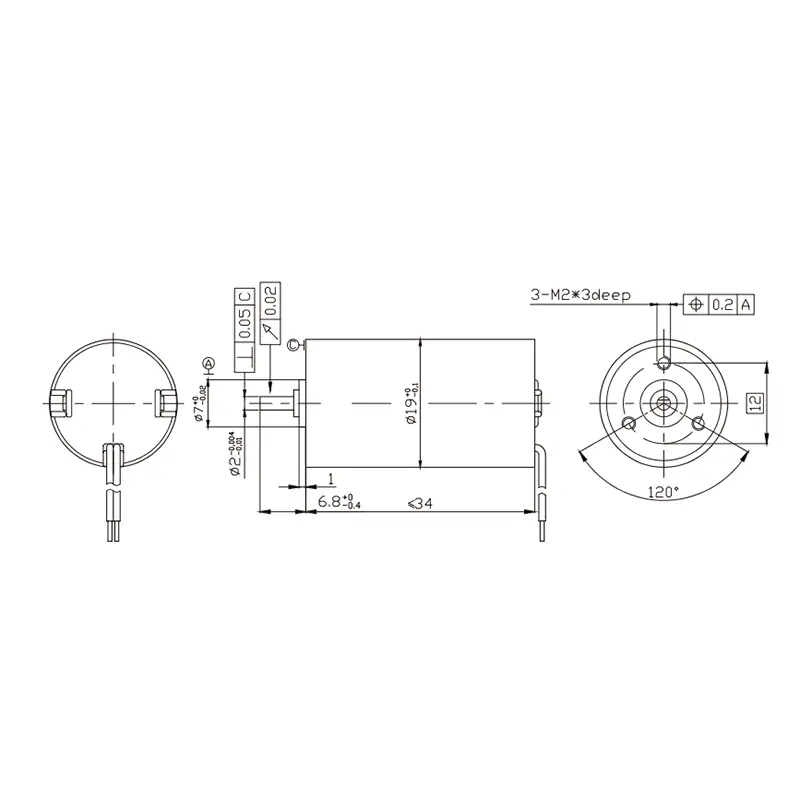

| Max.Deep Of Screw Installation | 3mm | |

Overview of Coreless DC Motor

1. What is the Coreless DC Motor?

Coreless DC Motor is a type of micro special motor, belonging to DC permanent magnet servo control motor. It breaks through the traditional fixed rotor structure of motors in terms of structure and adopts a coreless fixed/rotor structure. This novel fixed rotor structure completely eliminates the energy loss caused by eddy currents formed by the iron core.

At the same time, the weight and moment of inertia of the Coreless DC motor are significantly reduced, thereby reducing the mechanical energy loss of the stator/rotor itself. Due to the structural changes of the stator and rotor, the operating characteristics of the motor have been greatly improved. It not only has outstanding energy-saving features, but more importantly, it has control and drag characteristics that iron core motors cannot achieve. Coreless dc motor have outstanding energy-saving characteristics, sensitive and convenient control characteristics, and stable operating characteristics, with obvious technical advantages. As an efficient energy conversion device, it represents the development direction of electric motors in many fields.

Coreless DC Motor is a type of micro special motor, belonging to DC permanent magnet servo control motor. It breaks through the traditional fixed rotor structure of motors in terms of structure and adopts a coreless fixed/rotor structure. This novel fixed rotor structure completely eliminates the energy loss caused by eddy currents formed by the iron core.

At the same time, the weight and moment of inertia of the Coreless DC motor are significantly reduced, thereby reducing the mechanical energy loss of the stator/rotor itself. Due to the structural changes of the stator and rotor, the operating characteristics of the motor have been greatly improved. It not only has outstanding energy-saving features, but more importantly, it has control and drag characteristics that iron core motors cannot achieve. Coreless dc motor have outstanding energy-saving characteristics, sensitive and convenient control characteristics, and stable operating characteristics, with obvious technical advantages. As an efficient energy conversion device, it represents the development direction of electric motors in many fields.

2. Advantages of Coreless DC motor

Compared to traditional servo motors, Coreless dc motor eliminate the structure of the iron core, fundamentally solving various inherent problems of the iron core structure. The losses of iron core motors are divided into four categories, namely: stator winding copper loss, stator iron loss, rotor air friction loss, and rotor eddy current loss. The stator iron loss (including hysteresis loss, classical eddy current loss, and abnormal eddy current loss) and rotor eddy current loss can be avoided by eliminating the iron core structure of the stator or rotor. The magnitude of copper loss in the stator winding is influenced by multiple factors such as the operating frequency of the motor, the size of the winding conductor, and the arrangement position in the slot, and is therefore also affected by the removal of the iron core structure. The air friction loss of the rotor is proportional to the third power of the motor speed, so the wind wear of the rotor accounts for a large proportion in high-speed motors. If the rotor is replaced with a coreless structure, namely a cup-shaped self-supporting coil, which is small in size and light in weight, it can also achieve smaller wind wear at high speeds. The loss caused by the structure of the iron core motor is significant, especially under high-speed conditions. The design structure of the Coreless dc motor determines its characteristics, which can avoid various problems of the iron core motor.

Comparing Coreless dc motor with traditional iron core motors, it can be found that Coreless dc motor have many advantages due to their novel structural characteristics: no hysteresis, low electromagnetic interference, and the ability to achieve extremely high motor speeds. Due to the absence of iron core and tooth slot effect in the rotor structure, the corresponding iron loss is relatively small. The energy conversion efficiency is extremely high, with an energy utilization rate ranging from 75% to 90%. The rotor of a small inertia motor can achieve fast acceleration, excellent dynamic response performance, good starting and braking performance, fast response speed, small mechanical time constant, and some products can reach less than 10ms. In high-speed operation, the speed regulation is sensitive and has relatively reliable operational stability. The energy density of Coreless dc motor is much higher than other motors, and compared with iron core motors of the same power, the weight can be reduced by half.

Compared to traditional servo motors, Coreless dc motor eliminate the structure of the iron core, fundamentally solving various inherent problems of the iron core structure. The losses of iron core motors are divided into four categories, namely: stator winding copper loss, stator iron loss, rotor air friction loss, and rotor eddy current loss. The stator iron loss (including hysteresis loss, classical eddy current loss, and abnormal eddy current loss) and rotor eddy current loss can be avoided by eliminating the iron core structure of the stator or rotor. The magnitude of copper loss in the stator winding is influenced by multiple factors such as the operating frequency of the motor, the size of the winding conductor, and the arrangement position in the slot, and is therefore also affected by the removal of the iron core structure. The air friction loss of the rotor is proportional to the third power of the motor speed, so the wind wear of the rotor accounts for a large proportion in high-speed motors. If the rotor is replaced with a coreless structure, namely a cup-shaped self-supporting coil, which is small in size and light in weight, it can also achieve smaller wind wear at high speeds. The loss caused by the structure of the iron core motor is significant, especially under high-speed conditions. The design structure of the Coreless dc motor determines its characteristics, which can avoid various problems of the iron core motor.

Comparing Coreless dc motor with traditional iron core motors, it can be found that Coreless dc motor have many advantages due to their novel structural characteristics: no hysteresis, low electromagnetic interference, and the ability to achieve extremely high motor speeds. Due to the absence of iron core and tooth slot effect in the rotor structure, the corresponding iron loss is relatively small. The energy conversion efficiency is extremely high, with an energy utilization rate ranging from 75% to 90%. The rotor of a small inertia motor can achieve fast acceleration, excellent dynamic response performance, good starting and braking performance, fast response speed, small mechanical time constant, and some products can reach less than 10ms. In high-speed operation, the speed regulation is sensitive and has relatively reliable operational stability. The energy density of Coreless dc motor is much higher than other motors, and compared with iron core motors of the same power, the weight can be reduced by half.

3. Classification of Coreless dc motor

(1) Brushed Coreless dc motor and brushless Coreless dc motor

Coreless dc motor can be divided into brushed Coreless dc motor and brushless Coreless dc motor according to the commutation method. The difference in structure between brushed and brushless Coreless dc motor lies in the working mode of the fixed rotor and whether there is a commutator.

There are differences in the structure between brushed coreless dc motors and brushless motors:

① Brushed coreless dc motor:

The main components include a hollow cup coil with a commutator, permanent magnets, commutator brushes, and commutator brush brackets. The commutator uses mechanical brushes, the permanent magnets are the stator, and the hollow cup coil is the rotor;

(1) Brushed Coreless dc motor and brushless Coreless dc motor

Coreless dc motor can be divided into brushed Coreless dc motor and brushless Coreless dc motor according to the commutation method. The difference in structure between brushed and brushless Coreless dc motor lies in the working mode of the fixed rotor and whether there is a commutator.

There are differences in the structure between brushed coreless dc motors and brushless motors:

① Brushed coreless dc motor:

The main components include a hollow cup coil with a commutator, permanent magnets, commutator brushes, and commutator brush brackets. The commutator uses mechanical brushes, the permanent magnets are the stator, and the hollow cup coil is the rotor;

② Brushless coreless dc motor:

The main components include hollow cup coils, permanent magnet rotors, and Hall sensor PCBs. Among them, the commutator uses Hall sensors to detect the rotor magnetic field signal, converting mechanical commutation into electronic signal commutation, further simplifying the physical structure of the coreless dc motor. The rotor of the brushless coreless dc motor is a permanent magnet, and the stator is a hollow cup coil.

The main components include hollow cup coils, permanent magnet rotors, and Hall sensor PCBs. Among them, the commutator uses Hall sensors to detect the rotor magnetic field signal, converting mechanical commutation into electronic signal commutation, further simplifying the physical structure of the coreless dc motor. The rotor of the brushless coreless dc motor is a permanent magnet, and the stator is a hollow cup coil.

(2) Brushless coreless dc motor has better performance in terms of speed, weight, power to volume ratio, etc

Compared to brushed coreless dc motors, brushless coreless dc motors have better performance, higher upper speed limit, smaller weight, and higher power to volume ratio, but they are more expensive.

Compared to brushed coreless dc motors, brushless coreless dc motors have better performance, higher upper speed limit, smaller weight, and higher power to volume ratio, but they are more expensive.

4. Core components

The main components of the coreless dc motor include hollow cup coils, outer shell, bearings, lower shell, upper shell, permanent magnets, etc. Among them, the key component of the coreless dc motor is the coreless coil, which has no other supporting structure and is completely made of wire winding. The key factors determining the performance of coreless dc motors include the shape design, neat arrangement, and full slot filling rate of the coreless coil.

The main components of the coreless dc motor include hollow cup coils, outer shell, bearings, lower shell, upper shell, permanent magnets, etc. Among them, the key component of the coreless dc motor is the coreless coil, which has no other supporting structure and is completely made of wire winding. The key factors determining the performance of coreless dc motors include the shape design, neat arrangement, and full slot filling rate of the coreless coil.

Core barriers

The overall assembly process of the coreless dc motor is similar to that of ordinary motors, and its core technical barrier lies in the self-supporting winding technology of the stator/rotor.

The key to achieving self-supporting windings lies in the design of the winding process

There are many types of windings for coreless dc motors, including disc winding, straight winding, diagonal winding, concentric winding, stacked winding, etc

The key to achieving self-supporting windings lies in the design of the winding process

There are many types of windings for coreless dc motors, including disc winding, straight winding, diagonal winding, concentric winding, stacked winding, etc

(1)Straight winding type

The effective conductor of the straight wound component is parallel to the armature axis and belongs to a concentrated winding. This winding method has a high slot filling rate, thin walls in the middle of the winding cup, and due to the uneven and stacked arrangement of enameled wires, the entire hollow cup coil is arranged in a disorderly manner, leaving a routing allowance at the end, resulting in a higher end size.

(2)Oblique winding type

The inclined winding type, also known as the honeycomb winding, requires the effective edge of the component to be inclined at a certain angle to the armature axis in order to be continuously wound. This winding method results in a smaller end size, and due to the oblique winding type requiring a certain cable angle, the enameled wires overlap with each other, resulting in a lower groove filling rate. Faulhaber uses oblique winding coils, which are automatically wound and formed in one go with high qualification rate. The flatness and consistency of the winding cup are also very good.

(3)Concentric winding (diamond winding)

Concentric winding, also known as diamond shaped winding or saddle shaped winding, is a method of first winding multiple single diamond shaped coils and then arranging the wires. The coils are generally made of self-adhesive square wires for easy winding and fixing. Then, according to the size requirements of the product design, the individual coils are shaped, and the formed coils are fixed in a circular shape using specialized fixtures, ultimately forming a cup-shaped shape. This method is convenient for controlling the size of the hollow cup after shaping, improving the slot filling rate, and has high production efficiency, making it suitable for mass production. The power density of the concentric winding Coreless dc motor is relatively high, and the Swiss Maxon motor adopts the saddle shaped winding method, which has excellent motor product performance. Our company's products also use this winding method.

Coreless dc motor application field

Coreless dc motors widely used in high-precision industries such as aerospace, medical, and automation can be used in the following scenarios:

① The hollow cup electric motor can meet the technical requirements of fast response follow-up systems, such as rapid adjustment of missile flight direction, high magnification optical drive follow-up control, fast automatic focusing, high-sensitivity recording and detection equipment, industrial robots, bionic prostheses, etc.

② For products that require stable and long-lasting driving components, such as various portable instruments, personal equipment, and field operation instruments, using a Coreless dc motor with the same power supply can extend the power supply time by more than twice compared to traditional DC motors.

③ Various aircraft, including aviation, aerospace, and model aircraft, can greatly reduce their weight by utilizing the advantages of hollow cup electric motors, such as light weight, small size, and low energy consumption.

④ Optical instruments, medical equipment, etc. are subdivided into applications such as dental equipment, micro pumps, infrared lenses, pipetting modules, electric grippers, robotic hands, dispensing valves, surgical tools, etc.

① The hollow cup electric motor can meet the technical requirements of fast response follow-up systems, such as rapid adjustment of missile flight direction, high magnification optical drive follow-up control, fast automatic focusing, high-sensitivity recording and detection equipment, industrial robots, bionic prostheses, etc.

② For products that require stable and long-lasting driving components, such as various portable instruments, personal equipment, and field operation instruments, using a Coreless dc motor with the same power supply can extend the power supply time by more than twice compared to traditional DC motors.

③ Various aircraft, including aviation, aerospace, and model aircraft, can greatly reduce their weight by utilizing the advantages of hollow cup electric motors, such as light weight, small size, and low energy consumption.

④ Optical instruments, medical equipment, etc. are subdivided into applications such as dental equipment, micro pumps, infrared lenses, pipetting modules, electric grippers, robotic hands, dispensing valves, surgical tools, etc.

2. The application scenarios of Coreless dc motors are gradually expanding from high-precision fields to civilian fields

At present, Coreless dc motors are mainly used in high-precision industries such as aerospace, medical, and industrial automation, and gradually developed into civilian fields such as electric tools. Coreless dc motors have the

characteristics of high sensitivity, stable operation, and strong control, which meet the strict requirements of electric drive in high-precision fields. Therefore, they are mainly used in high-precision fields such as aerospace, medical equipment, industrial automation, and robotics. At the same time, Coreless dc motors are gradually being applied in civilian fields, such as office automation, power tools, etc.

At present, Coreless dc motors are mainly used in high-precision industries such as aerospace, medical, and industrial automation, and gradually developed into civilian fields such as electric tools. Coreless dc motors have the

characteristics of high sensitivity, stable operation, and strong control, which meet the strict requirements of electric drive in high-precision fields. Therefore, they are mainly used in high-precision fields such as aerospace, medical equipment, industrial automation, and robotics. At the same time, Coreless dc motors are gradually being applied in civilian fields, such as office automation, power tools, etc.

Hot Tags:

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.